how to calibrate a refractometer for coolant|refractometer for coolant cutting fluid : custom Calibrate the refractometer with a standard solution (typically included with the refractometer) before use. Since the reading will be adversely affected by changes in temperature, it is best to calibrate at room temperature, . When it comes to Reinforced Autoclaved Aerated Concrete (RAAC), understanding the factors that contribute to its vulnerabilities is essential for ensuring the longevity and safety of structures. RAAC structures .The aerated concrete is then steam cured under pressure in an autoclave, increasing its structural stability and final strength. The resulting AAC blocks are durable, fire and pest resistant, thermally efficient, and lightweight .

{plog:ftitle_list}

Autoclaved aerated concrete is a lightweight, durable, and energy-efficient building material made from natural raw materials such as sand, cement, lime, gypsum, and water. One of the main advantages of aerated concrete is its .

Calibrate the refractometer with a standard solution (typically included with the refractometer) before use. Since the reading will be adversely affected by changes in temperature, it is best to calibrate at room temperature, .When calibrating a refractometer, it’s imperative to calibrate the refractometer with the same water you’re using to mix your coolant. Everyone’s water is different, but you’ll want the refractometer . Calibrate the refractometer with a standard solution (typically included with the refractometer) before use. Since the reading will be adversely affected by changes in temperature, it is best to calibrate at room temperature, or within the test environment.When calibrating a refractometer, it’s imperative to calibrate the refractometer with the same water you’re using to mix your coolant. Everyone’s water is different, but you’ll want the refractometer to read “0” with your specific water BEFORE measuring the concentration of the coolant.

A refractometer is an essential tool for accurately measuring the concentration of your coolant mixture. Here’s how to use it: Calibrate the Refractometer: Before taking any measurements, calibrate your refractometer using distilled water.

Using a Refractometer: Check the calibration of your refractometer. Water at 68° F should read 0.0 percent Brix. Open the cover plate and place a drop of plain water (no coolant) on the prism surface (see Figure 1). Close the cover plate to spread water over surface.

A refractometer is used to measure the freezing point of vehicle coolant, washer fluid, and potentially also testing battery electrolyte. This short video demonstrates how to use a. That way I can calibrate the refractometer and see what concentration I actually have when checking the coolant. In your case I'd make up 7%,8% and 9% concentrations to calibrate the refractometer. Your adding 16L of concentrate to 184L of water to get 8% is correct.

Calibrate the refractometer with a standard solution before use. Since the reading will be affected by temperature changes, it's best to calibrate at the temperature of the test environment. If this is not possible, correction charts may be used. Refractometers provide a quick, easy, and accurate way of testing and controlling coolant concentration. Watch Kurt Repsher demonstrate the correct way to us. Each coolant has its own refractometer factor which can be found on a product data sheet or determined using known sample concentrations. This refractometer factor can be multiplied by the °Brix reading taken from the refractometer to .

How to Calibrate a Refractometer Step 1 - Place 2 to 3 drops of distilled water on prism surface and press cover down lightly. Step 2 - Aim refractometer in direction of light and look through the unit eyepiece. Calibrate the refractometer with a standard solution (typically included with the refractometer) before use. Since the reading will be adversely affected by changes in temperature, it is best to calibrate at room temperature, or within the test environment.When calibrating a refractometer, it’s imperative to calibrate the refractometer with the same water you’re using to mix your coolant. Everyone’s water is different, but you’ll want the refractometer to read “0” with your specific water BEFORE measuring the concentration of the coolant. A refractometer is an essential tool for accurately measuring the concentration of your coolant mixture. Here’s how to use it: Calibrate the Refractometer: Before taking any measurements, calibrate your refractometer using distilled water.

Using a Refractometer: Check the calibration of your refractometer. Water at 68° F should read 0.0 percent Brix. Open the cover plate and place a drop of plain water (no coolant) on the prism surface (see Figure 1). Close the cover plate to spread water over surface. A refractometer is used to measure the freezing point of vehicle coolant, washer fluid, and potentially also testing battery electrolyte. This short video demonstrates how to use a.

That way I can calibrate the refractometer and see what concentration I actually have when checking the coolant. In your case I'd make up 7%,8% and 9% concentrations to calibrate the refractometer. Your adding 16L of concentrate to 184L of water to get 8% is correct.

Calibrate the refractometer with a standard solution before use. Since the reading will be affected by temperature changes, it's best to calibrate at the temperature of the test environment. If this is not possible, correction charts may be used.

Refractometers provide a quick, easy, and accurate way of testing and controlling coolant concentration. Watch Kurt Repsher demonstrate the correct way to us. Each coolant has its own refractometer factor which can be found on a product data sheet or determined using known sample concentrations. This refractometer factor can be multiplied by the °Brix reading taken from the refractometer to .

meniscus tear special test

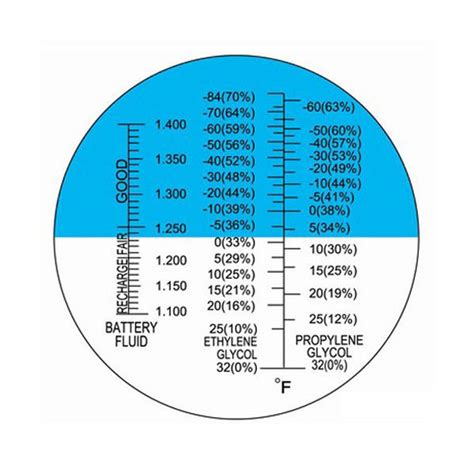

refractometer reading chart

meniscus tear squat test

meniscus tear symptoms test

orthopedic test for hip labral tear

pectoralis minor tear test

The high resource efficiency of autoclaved aerated concrete contributes to a lower environmental impact than conventional concrete, from raw material processing to the disposal of aerated concrete waste. Due to continuous improvements in efficiency, the production of aerated concrete blocks requires relatively little raw materials per m of product and is five times less than the production of other building materials. There is no loss of raw materials in the production proces.

how to calibrate a refractometer for coolant|refractometer for coolant cutting fluid